Chemistry, precisely

We scale metal-organic frameworks to reduce the negative impact of chemical products and processes on human health and the environment.

MOF solutions designed to tackle the greatest challenges facing global industries now and in the future

We help our customers achieve their innovation and sustainability objectives by improving the efficiency of the critical industrial products and processes powering global growth.

MOF market leaders

We are the market leader in metal-organic frameworks (MOFs), a transformative precision chemistry platform that can capture hazardous chemicals with incredible precision.

Speed meets scale

Our world-class platform integrates MOFs into existing products and processes, merging chemistry innovation with manufacturing at industrial scale.

Solving Industrial Challenges

Precision chemistries, at scale

Next-Generation Chemical Delivery

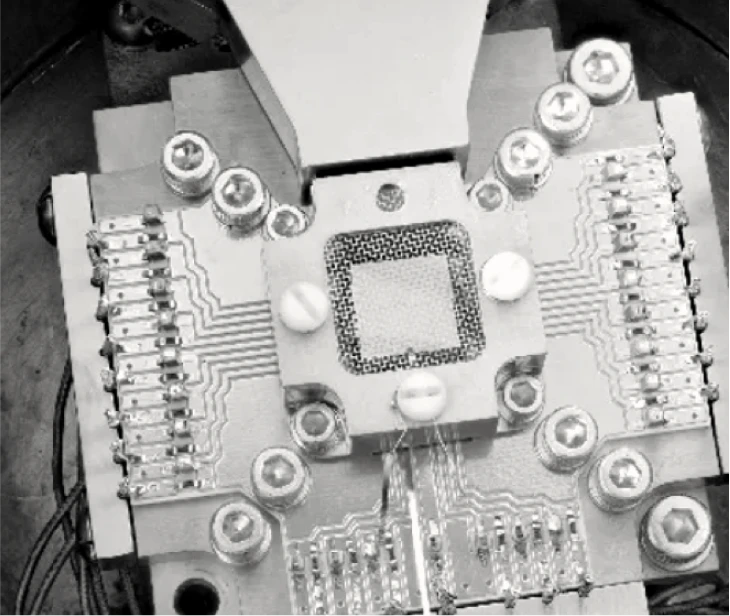

Enabling our digital future

The global semiconductor industry trusts ION-X® delivery systems to transport critical, yet hazardous electronic materials to the tools fabricating chips one atomic layer at a time.

Powered by

ION-X®

The future of chemical protection

Protection for mission critical environments

SENTINEL™ filtration enables next-level chemical protection and decontamination in a single material, transforming how war fighters and front line workers are protected from chemical threats.

Powered by

SENTINEL™

Reducing emissions sustainably

Powering a net zero future

Numat’s SENTINEL™ filtration shields our built environment from industrial emissions by precisely capturing and separating hard-to-abate toxic and greenhouse gases.

Powered by

SENTINEL™

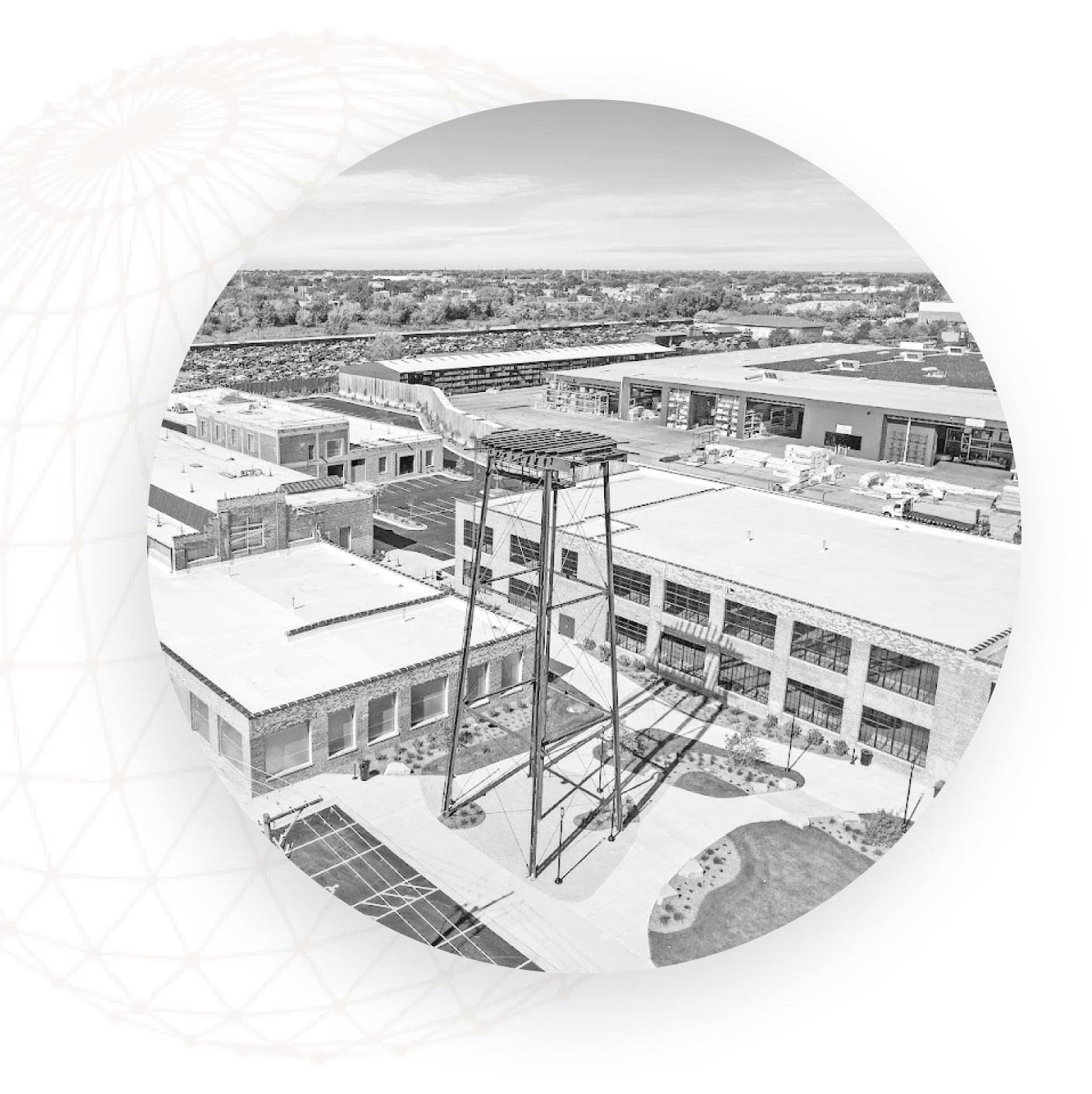

Precision chemistries at scale

Our facilities

Today, we operate the world’s only ISO 9001:2015 certified facility for the final assembly of MOF products sold into leading edge industrial applications.

In 2024, Numat is relocating its headquarters to a former foundry in Chicago, being repurposed to a state-of-the art nanofabrication and manufacturing center of excellence.

Industries We Serve

Semiconductor

Life cycle management of critical electronic materials

Extreme Environments

Next-generation chemical and biological protection solutions

Energy

Decarbonizing chemical separations and reducing emissions intensity

Careers at Numat

Be part of something bigger

Numat is built on a future-driven culture, powered by an extraordinary team. We are unified by a shared set of values and a passion to drive industrial efficiency through chemistry innovation.